Canvas robotics is revolutionizing the way we approach design and manufacturing. As I dive into this fascinating field, I’m captivated by how these innovative systems blend creativity with technology, enabling artists and engineers alike to push the boundaries of what’s possible. In a world where precision and efficiency are paramount, canvas robotics offers a unique solution that streamlines processes and enhances productivity. From intricate art installations to complex engineering projects, these robotic systems are not just tools; they’re partners in creativity. Join me as I explore the transformative impact of canvas robotics and discover how it’s shaping the future of various industries.

- Integration of Technology and Art: Canvas robotics merges advanced technology with artistic expression, enhancing both creative processes and engineering efficiency.

- Real-Time Feedback and Adaptability: These systems allow instant modifications and feedback during the design process, significantly improving productivity and precision.

- Wide Applications Across Industries: Canvas robotics can be utilized in diverse sectors such as fashion, automotive, and education, streamlining operations and fostering innovation.

- Cost-Effectiveness: Automating intricate tasks with canvas robotics reduces labor costs and material waste, leading to significant savings in production.

- Learning and Collaboration Enhancement: In educational settings, canvas robotics fosters hands-on learning, encouraging creativity and the development of essential STEM skills among students.

- Challenges to Adoption: High initial costs, technical complexity, and maintenance needs present challenges that businesses must navigate when adopting canvas robotics.

Canvas Robotics

Canvas robotics integrates advanced technology with artistic expression and engineering efficiency. These systems utilize automation and robotics to optimize designs and streamline manufacturing processes. By merging creativity with precision, canvas robotics transforms traditional workflows, enabling artists and engineers to produce complex designs that were previously unattainable.

Canvas robotics operates on a framework that enhances collaboration and fosters innovation. Artists use these systems to create intricate patterns, while engineers harness their capabilities to develop prototypes faster. With the ability to adjust parameters in real time, these robots provide immediate feedback, which increases productivity and accuracy.

The applications of canvas robotics span various industries, from fashion to automotive. In fashion, designers employ canvas robotics to produce customized fabrics, while the automotive sector utilizes them for precise component fabrication. The scalability and adaptability of these systems make them indispensable in modern design and manufacturing.

By incorporating canvas robotics, businesses gain a competitive edge, merging art and technology seamlessly. This fusion not only opens new avenues for creative exploration but also sets a benchmark for efficiency and quality in production.

Key Features of Canvas Robotics

Canvas robotics incorporates advanced technologies and user-friendly interfaces that significantly enhance creative and engineering workflows. These systems offer a blend of innovation and accessibility, driving productivity and collaboration across various industries.

Advanced Technologies

Canvas robotics leverage cutting-edge technologies like artificial intelligence, machine learning, and computer vision. These technologies enable precise motion control and real-time visual feedback, allowing for intricate designs to come to life with unmatched accuracy. Systems often include advanced sensors that monitor environmental conditions, optimizing performance as conditions change. Integration with CAD software facilitates seamless design transitions from conception to production, ensuring efficiency and quality at every stage.

User-Friendly Interface

User-friendly interfaces characterize canvas robotics, making these systems accessible to a wide range of users. Intuitive design features allow artists and engineers to interact effortlessly with the technology, streamlining the creation process. Touchscreen controls, customizable settings, and guided tutorials enhance the user experience, reducing the learning curve. Real-time updates and interactive adjustments empower users to modify parameters instantly, fostering creativity without the hindrance of complex programming.

Applications of Canvas Robotics

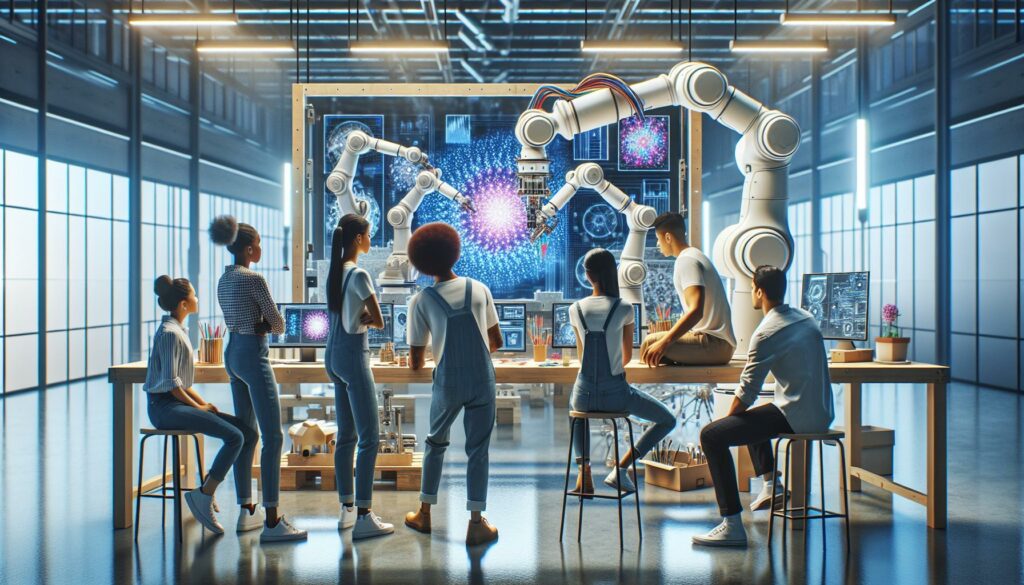

Canvas robotics showcases a wide range of applications across multiple sectors, driving innovation in educational and industrial environments.

Educational Purposes

Canvas robotics serves as an invaluable tool in educational settings, enhancing learning experiences in art and engineering disciplines. Students engage in hands-on learning, utilizing these systems to create intricate projects that foster creativity and technical skills. Robotics programs integrate canvas technology, allowing learners to explore computational design, automation, and problem-solving in real-time. Workshops and classes often include project-based activities, encouraging teamwork and collaboration among peers. By incorporating canvas robotics, educational institutions prepare students for future careers in STEM fields while igniting their passion for creativity.

Industrial Uses

Canvas robotics significantly impacts various industries by streamlining manufacturing processes and enhancing product quality. In fashion, designers harness these systems to produce customized fabrics and intricate patterns, reducing lead times and minimizing waste. In the automotive sector, precise component fabrication ensures high standards of quality and efficiency, allowing manufacturers to maintain competitiveness in a fast-paced market. Additionally, canvas robotics aids in architecture and construction, facilitating the creation of complex structures and prototypes. The adaptability of these systems enables them to cater to diverse production needs, making them an essential asset in modern manufacturing environments.

Benefits of Using Canvas Robotics

Canvas robotics offers numerous advantages, significantly impacting both creative and industrial fields. By enhancing efficiency and facilitating collaboration, these systems transform the way I approach design and production.

Cost-Effectiveness

Cost-effectiveness stands out as a primary benefit of canvas robotics. Automation reduces labor costs by minimizing the need for manual intervention. For example, automating intricate tasks can slash production times by up to 50%, allowing for faster delivery of products. The precision of canvas robotics also lessens material waste, directly contributing to savings. By ensuring that designs are executed accurately, I achieve higher yields and reduce costs associated with rework and scrap materials.

Enhanced Learning Experience

Canvas robotics enhances the learning experience, particularly in educational environments. Students actively engage in hands-on projects, bridging the gap between creativity and technical skills. By utilizing canvas robotics, I foster an environment that encourages exploration and innovation. Programs incorporating this technology enable students to work collaboratively while developing essential STEM competencies. Real-time feedback from these systems allows for iterative learning, empowering students to enhance their designs quickly while gaining practical experience in both art and engineering.

Challenges and Limitations

Canvas robotics faces several challenges and limitations that impact its effectiveness and adoption across industries. Understanding these obstacles is crucial for optimizing the integration of these systems into workflows.

High Initial Investment Costs

High initial investment costs can deter businesses from adopting canvas robotics. The price of purchasing advanced machines, software licenses, and necessary infrastructure often leads to budget constraints, especially for small enterprises.

Technical Complexity

Technical complexity raises the barrier to entry for many users. While user-friendly interfaces exist, mastering sophisticated programming and troubleshooting techniques demands significant technical knowledge, which may discourage less experienced users.

Maintenance and Repair Needs

Maintenance and repair needs can disrupt production processes. Frequent calibration and updates are necessary to maintain optimal performance. Organizations must allocate resources for ongoing maintenance, contributing to overall operational costs.

Limited Material Compatibility

Limited material compatibility restricts the versatility of canvas robotics. Not all materials perform well within robotic systems, posing challenges for diverse applications. This limitation can inhibit creativity and flexibility in design.

Dependency on External Factors

Dependency on external factors, such as software updates and network connectivity, can affect operational efficiency. Interruptions in service or compatibility issues may lead to downtime, impacting productivity and project timelines.

Industry Regulation

Industry regulation may impose additional barriers. Certain sectors, particularly in manufacturing and healthcare, require adherence to strict compliance standards. Navigating these regulations can complicate the integration of canvas robotics into existing processes.

Skill Gap and Training Requirements

Skill gap and training requirements present challenges for effective implementation. Organizations need to invest in staff training to leverage the benefits of canvas robotics. The time and resources needed for workforce development can slow down the adoption process.

Understanding these challenges and limitations enables organizations to strategize effectively when integrating canvas robotics into their operations. It helps in identifying solutions and potential adaptations to overcome obstacles and fully utilize the advantages of these innovative systems.

Canvas robotics is reshaping how we approach design and manufacturing. By blending creativity with cutting-edge technology it opens up new possibilities for artists and engineers alike. The efficiency and precision these systems offer not only enhance productivity but also encourage collaboration across various industries.

As I explore the growing applications of canvas robotics I’m excited about the potential it holds for the future. From fashion to automotive and beyond these innovative tools are setting new standards in quality and efficiency. While challenges exist the benefits far outweigh them. Embracing canvas robotics could be the key to unlocking unprecedented levels of creativity and innovation in our work.