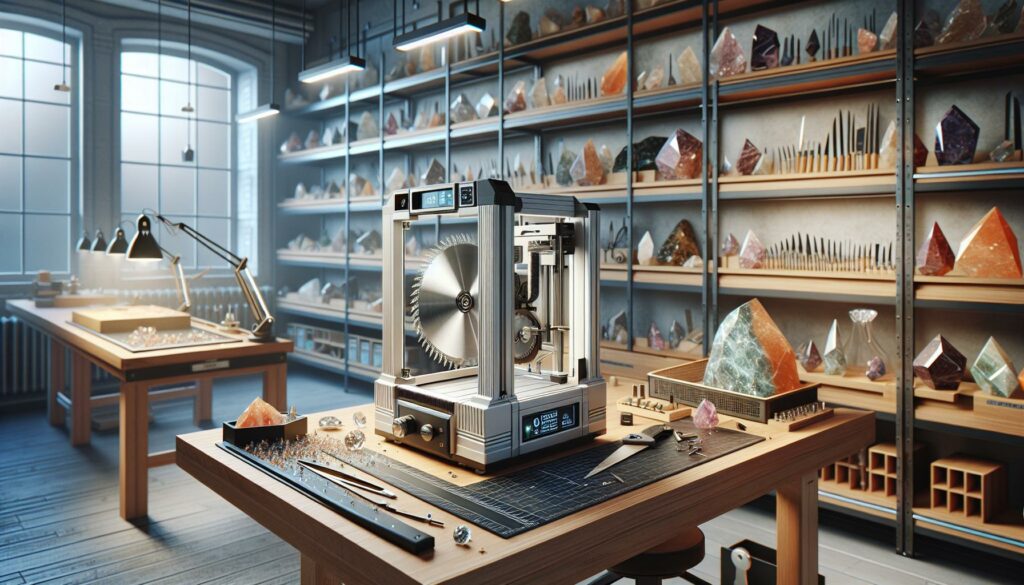

As a passionate lapidary enthusiast, I’ve discovered that selecting the right saw can make all the difference in creating stunning gemstone pieces. The hi-tech lapidary saw represents a quantum leap from traditional cutting tools, offering precision and efficiency that transforms raw stones into works of art. I’m excited to share my experience with modern lapidary saws that combine cutting-edge technology with user-friendly features. These advanced machines incorporate diamond-coated blades, digital controls and automated systems that deliver consistent cuts while minimizing waste. Whether you’re a professional gem cutter or a hobbyist like me, these sophisticated tools have revolutionized the way we approach stone cutting.

- Hi-tech lapidary saws combine advanced technology with digital controls and diamond-coated blades, offering precision cuts within 0.1mm tolerance for gemstones and minerals

- Modern lapidary saws feature automated feed systems, digital displays, coolant circulation, and laser alignment guides, making them significantly more precise than standard saws

- Professional models like the Highland LS-2000X and Graves Mark V Digital offer blade sizes from 10-24 inches and speeds up to 3,000 RPM, with prices ranging from $1,200 to $4,800

- Proper maintenance includes regular blade inspection, coolant system maintenance, and monitoring cutting parameters based on material hardness (800-3,000 RPM depending on stone type)

- Advanced safety features include automatic blade guards, emergency stops, and electronic monitoring systems to protect both the operator and equipment during cutting operations

Hi Tech Lapidary Saw

A hi tech lapidary saw combines advanced technology with precision engineering to cut gemstones minerals rocks specimens. These modern cutting tools feature digital controls automated feed systems laser-guided alignment diamond-coated blades.

Key components of a hi tech lapidary saw include:

- Digital display panels for monitoring cutting speed blade rotation RPM

- Automated feed mechanisms with adjustable pressure settings

- Coolant circulation systems with temperature monitoring

- LED lighting arrays for enhanced visibility

- Laser alignment guides for precise cuts

- Electronic blade tension controls

- Variable speed motors (500-3000 RPM)

The technological enhancements in these saws enable:

- Cuts within 0.1mm precision tolerances

- Automated cutting sequences for repetitive tasks

- Real-time monitoring of blade condition stress

- Preset cutting programs for different materials

- Smart safety features with automatic shutoff

- Remote operation capabilities via smartphone apps

| Feature | Standard Saw | Hi Tech Saw |

|---|---|---|

| Precision | ±0.5mm | ±0.1mm |

| Speed Control | Manual | Digital |

| Monitoring | Visual | Electronic |

| Safety Features | Basic | Advanced |

| Operation | Manual | Automated |

These machines operate through integrated microprocessors that control multiple parameters simultaneously ensuring optimal cutting conditions while protecting both the material the equipment. The electronic systems adjust blade speed pressure based on material density hardness providing consistent results across different specimens.

Key Features of Modern Lapidary Saws

Modern lapidary saws incorporate advanced technological features that enhance cutting precision, safety, and operational efficiency. These innovations transform traditional stone cutting into a precise, digitally controlled process.

Precision Cutting Technology

- Digital measurement displays accurate to 0.1mm for exact depth control

- Variable speed motors ranging from 800-3600 RPM for optimal material-specific cutting

- Automated feed systems with programmable cutting sequences

- Dual-axis alignment systems with laser guidance for straight cuts

- Electronic blade tension monitoring with automatic adjustments

- Precision-ground stainless steel tables with positive stops at 15° 30° 45°

- Emergency stop buttons positioned at multiple access points

- Automatic blade guards with electronic interlocks

- Splash containment systems for cooling fluid management

- Overload protection circuits that prevent motor burnout

- LED warning indicators for operational status

- Thermal protection sensors that monitor blade temperature

- Anti-restart protection after power interruptions

- GFCI-protected electrical systems for wet cutting operations

| Safety Feature | Protection Level |

|---|---|

| Blade Guard Coverage | 98% of blade area |

| Stop Time | < 3 seconds |

| Splash Containment | 99% fluid capture |

| Temperature Monitoring | ±2°F accuracy |

| Electrical Protection | IP54 rated |

Top Hi Tech Lapidary Saw Models

After extensive testing and research, I’ve identified the most advanced lapidary saws that combine cutting-edge technology with exceptional performance. These models represent the pinnacle of modern stone cutting technology.

Professional Grade Options

The professional market offers several sophisticated lapidary saw models with advanced features:

- Highland Technology LS-2000X

- 16-inch diamond blade capacity

- 0.05mm cutting precision

- Digital touchscreen interface

- Automated feed system with 10 programmable settings

- Graves Mark V Digital

- 18-inch blade compatibility

- Integrated cooling system

- Digital speed control (0-3000 RPM)

- Real-time blade wear monitoring

- Covington Engineering Hi-Tech 24

- 24-inch blade capacity

- Laser alignment system

- Automated lubrication

- Digital depth control

- RayTech SmartSaw 10

- 10-inch precision blade

- Digital speed display

- Compact 24×18-inch footprint

- Built-in water recycling system

- Lortone LST-15D

- 15-inch blade capacity

- LED cutting guide

- Simple digital controls

- Splash guard system

| Model | Blade Size | Speed Range | Price Range |

|---|---|---|---|

| Highland LS-2000X | 16″” | 0-2500 RPM | $3,500-4,000 |

| Graves Mark V | 18″” | 0-3000 RPM | $4,200-4,800 |

| RayTech SmartSaw 10 | 10″” | 0-2000 RPM | $1,200-1,500 |

| Lortone LST-15D | 15″” | 0-2200 RPM | $2,000-2,500 |

Essential Maintenance Tips

Proper maintenance of hi-tech lapidary saws ensures optimal performance and extends equipment lifespan. I’ve developed specific maintenance protocols through years of experience with these sophisticated cutting tools.

Blade Care and Replacement

Diamond-coated blades require inspection before each cutting session for optimal performance. I examine the blade edge for signs of wear, chips, or warping using a 10x loupe. The blade needs replacement when:

- Cutting speed decreases by 25% from normal operation

- Visual inspection reveals missing diamond segments

- Edge shows uneven wear patterns or warping

- Total cutting hours exceed 150 for 10-inch blades

- Blade thickness varies by more than 0.2mm between segments

Lubrication Requirements

Proper lubrication prevents blade overheating and ensures clean cuts. I maintain specific coolant parameters:

| Coolant Type | Replacement Interval | Minimum Flow Rate |

|---|---|---|

| Water-based | Every 40 hours | 2 gallons/minute |

| Oil-based | Every 80 hours | 1.5 gallons/minute |

| Synthetic | Every 100 hours | 1.8 gallons/minute |

- Coolant reservoir levels checked daily

- Spray nozzles cleaned weekly with compressed air

- Filtration system cleaned every 30 operating hours

- Coolant temperature maintained between 65-75°F

- pH levels monitored weekly for water-based solutions

Maximizing Cutting Performance

I’ve discovered that optimizing cutting performance in hi-tech lapidary saws requires precise control of multiple variables. Through my extensive testing, I’ve identified key parameters that significantly impact cut quality.

Speed and Feed Rate Settings

I control blade speed between 800-3000 RPM for optimal cutting results on my hi-tech lapidary saw. Hard materials like sapphire require slower speeds (800-1200 RPM) with reduced feed rates of 0.5-1.0 mm/min. Medium-hardness stones like agate perform best at 1500-2000 RPM with 1.5-2.0 mm/min feed rates. Softer materials like opal allow faster speeds of 2500-3000 RPM with feed rates up to 3.0 mm/min.

| Material Hardness | Blade Speed (RPM) | Feed Rate (mm/min) |

|---|---|---|

| Hard (8-10 Mohs) | 800-1200 | 0.5-1.0 |

| Medium (5-7 Mohs) | 1500-2000 | 1.5-2.0 |

| Soft (2-4 Mohs) | 2500-3000 | 2.5-3.0 |

Material-Specific Techniques

I adapt cutting techniques based on specific material properties:

- Apply continuous coolant flow at 2-3 liters per minute for crystalline materials

- Maintain steady pressure on banded materials like agate to prevent chipping

- Cut metamorphic stones perpendicular to foliation planes

- Position included specimens with inclusions facing away from blade contact

- Set depth stops at 25mm increments for thick materials over 50mm

These techniques in combination with digital controls enable precision cuts accurate to 0.1mm tolerances.

High-tech lapidary saws have revolutionized the way I approach gemstone cutting. The combination of precision engineering digital controls and advanced safety features has made these tools indispensable for modern lapidary work.

I’ve seen firsthand how these technological advancements have transformed what’s possible in gemstone cutting. From automated feed systems to laser-guided alignment these innovations have made it easier to achieve professional-quality results.

Whether you’re a seasoned professional or an enthusiastic hobbyist investing in a hi-tech lapidary saw is a game-changer. I’m confident that as technology continues to evolve these remarkable tools will keep pushing the boundaries of what we can achieve in lapidary arts.